Advantages of thermoset

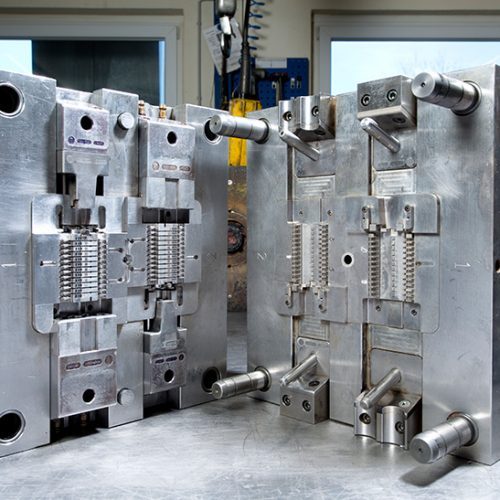

Thermoset is an incredibly lightweight material that can replace metal in particular in production. It is not only thermostable and dimensionally stable, but also inexpensive. By eliminating the need to rework thermoset, you also save yourself further costs.

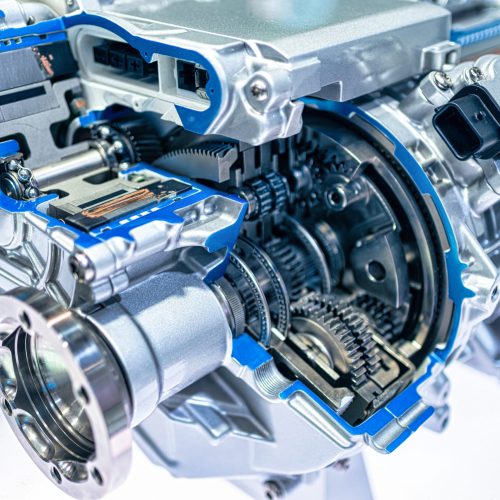

The resistance of the thermoset molded parts at high temperatures ensures a long service life.

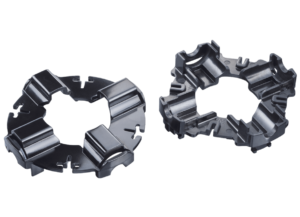

Thermoset molding parts are the ideal substitute for metal components because they cannot be deformed once they are hardened.

Due to the resistance to external influences, your molded parts permanently retain their original shape.

Chemical resistance opens up new application possibilities in a wide range of industries

Benefit from low raw material prices and attractive processing costs when using thermoset.

Due to the low weight of thermoset compared to metal, molding parts can be produced that are lighter while maintaining the same dimensional stability.

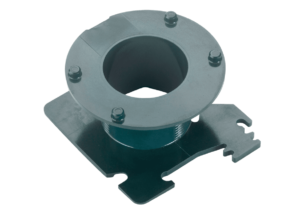

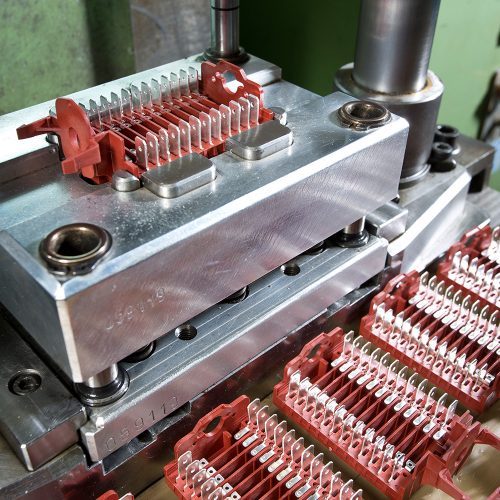

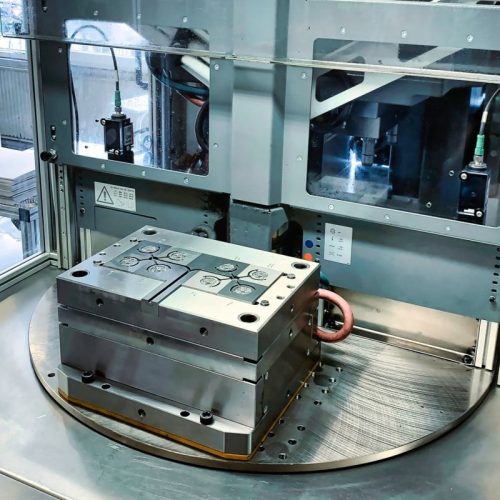

By injecting thermoset into the desired shape, we simplify your manufacturing process. This eliminates additional work and saves time and costs.

Through the combination of thermoset and inserts, we open up numerous innovative solutions for different areas of application for you