Benefits of thermoplastics

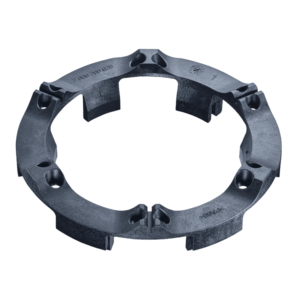

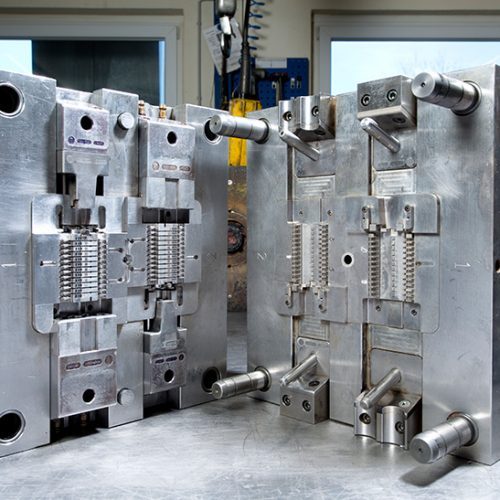

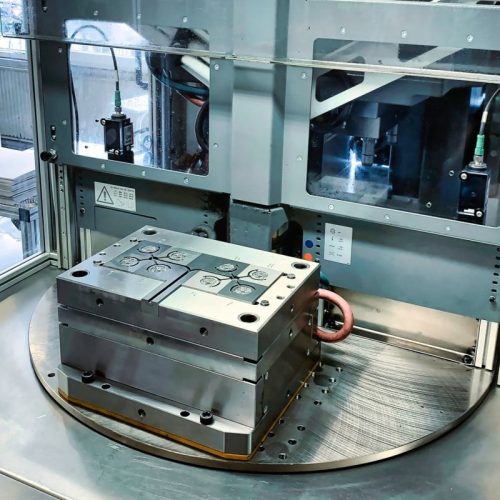

In a growing number of industries, the use of thermoplastics has gained significance due to the increasing demand for the production of high-quality plastic products. The process of thermoplastic injection molding is undoubtedly one of the most popular methods of manufacturing plastic parts.

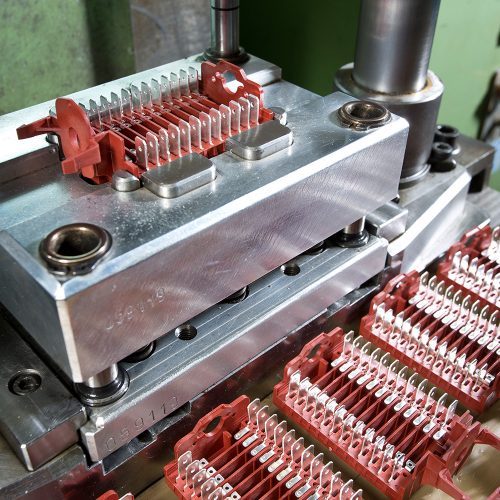

High-quality molded parts made of thermoplastic can be produced accurately, at high speed, and in high quantities. This provides ideal conditions for mass production with low unit costs.

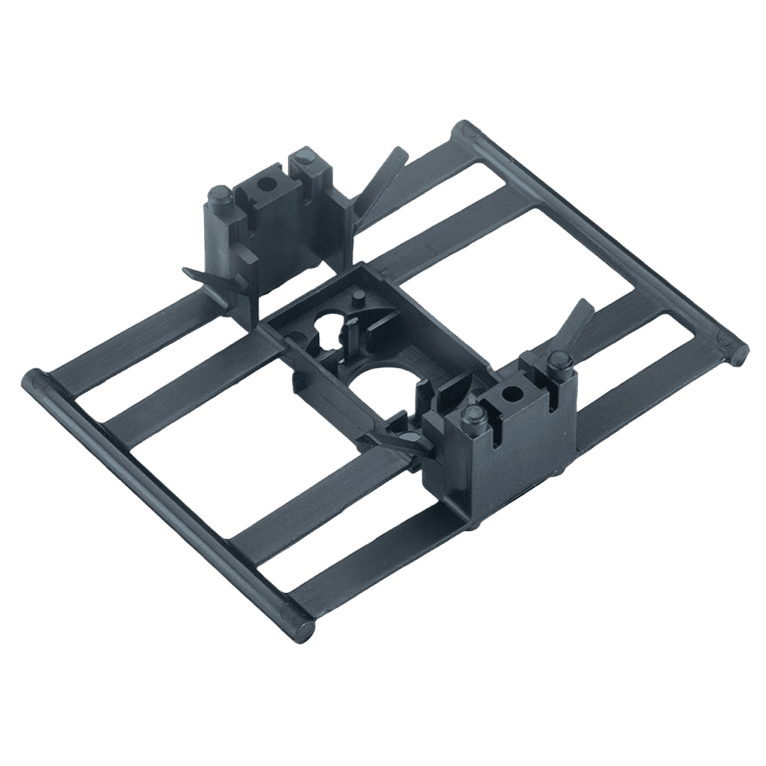

Thermoplastics can be welded, which is useful when a permanent bond cannot be guaranteed by gluing.

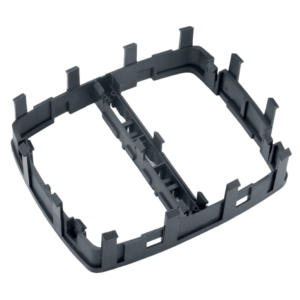

The high dimensional accuracy of thermoplastics enables the production of uniform and very precise plastic parts with little or no deviation.

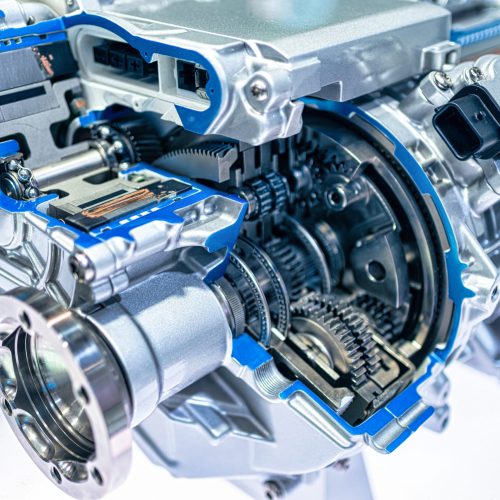

Compared to metals, the chemical resistance of thermoplastics offers new application possibilities in various industries.

Due to the largely automated process and the low material costs, thermoplastic molded parts can be produced with minimal effort.

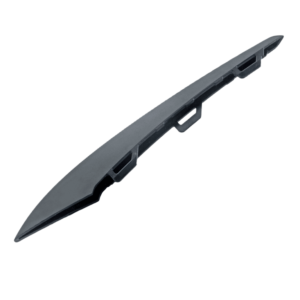

Due to the low weight of thermoplastics compared to metals, significant weight savings can be achieved in the final product.

By injecting thermoplastics into the desired shape, we simplify your manufacturing process. This eliminates additional work and saves time and costs.

The process of insert molding with thermoplastic allows you to combine various materials without the need for welding or screwing.

The remaining material from production can be recycled and reused.