All from one source

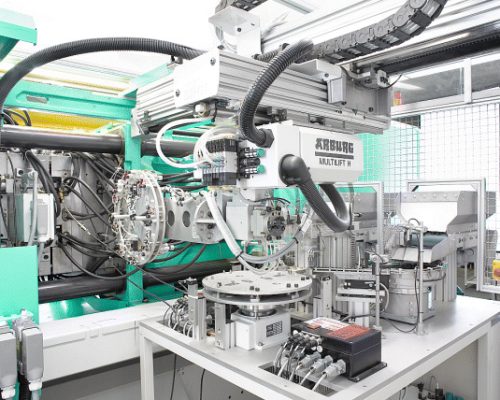

Services mold construction

Feasibility studies

Project Management

Development and

construction

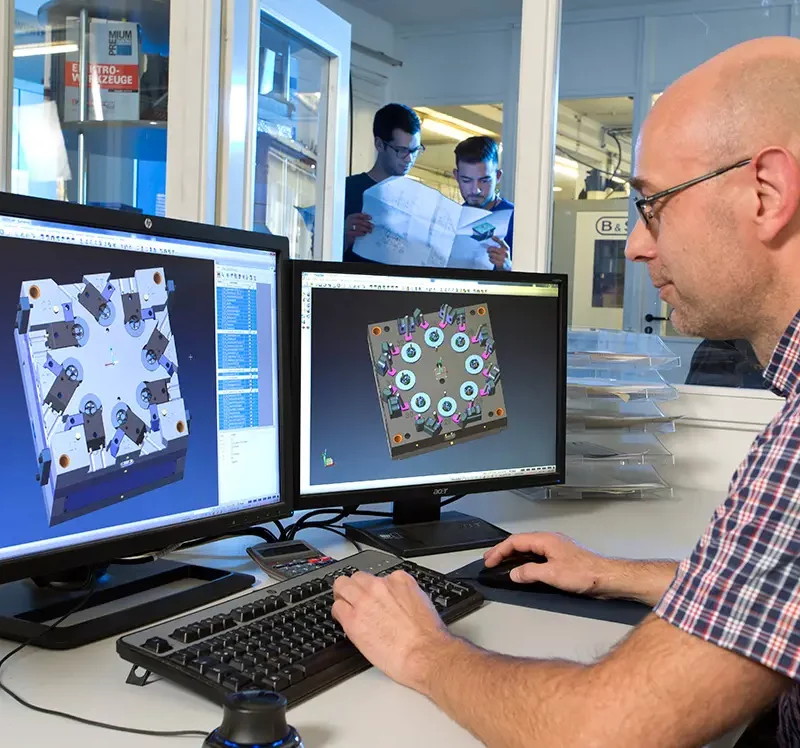

CAD/CAM processing

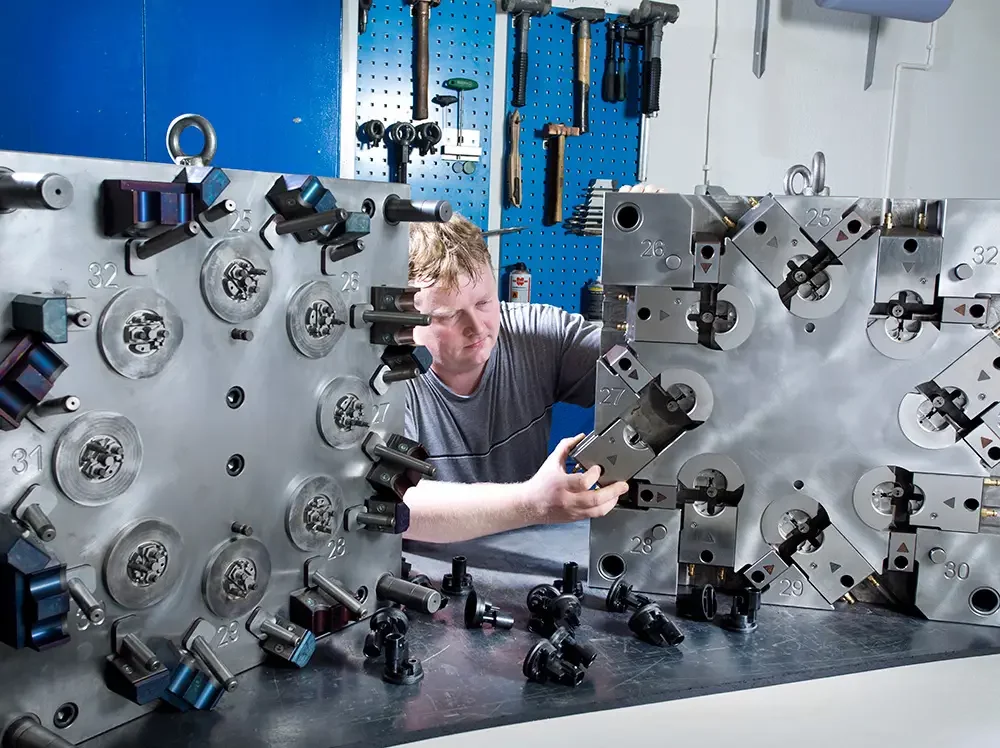

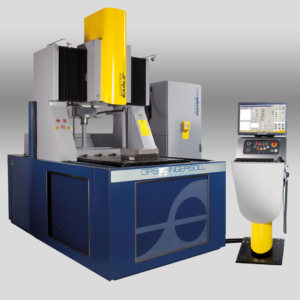

Production of

injection molds

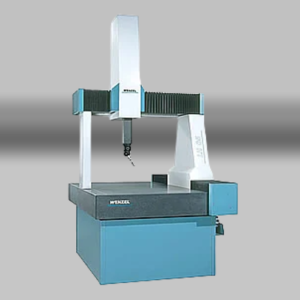

Quality management

Maintenance service for molds