In all areas of production we focus on high unit volumes and consistently high quality. Fully and partially automated workstations can be configured to meet the requirements of the customer products.

The link between modern automation and manual assembly is just one of the many strengths of B&S. Several decades of experience in the production of molded parts and assembles had led us to pole position in this market segment.

In today’s era, where efficiency and productivity are becoming increasingly important, it is essential for companies to explore automation solutions. However, it is not only about automating standardized processes, but also about developing customized solutions that are precisely tailored to the needs and requirements of our customers.

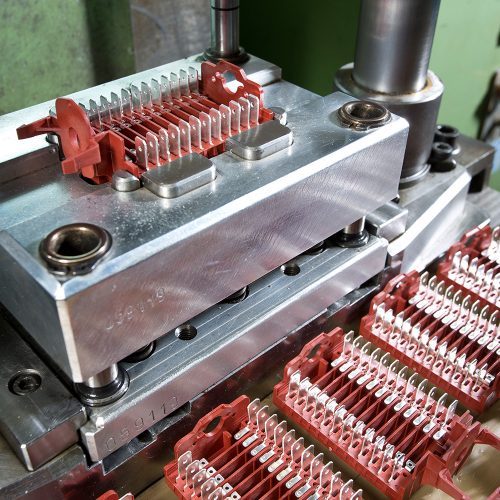

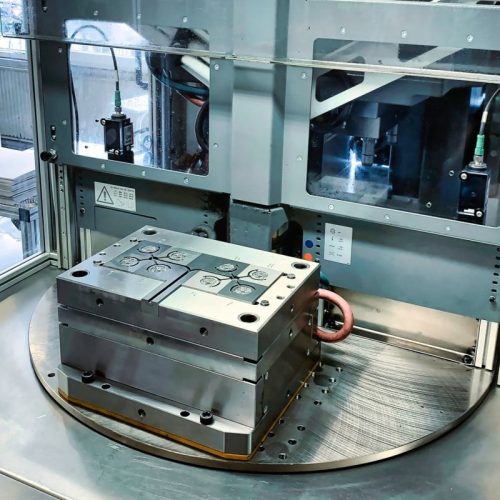

In order to be able to carry out production even more effectively and cost-effectively, we manufacture a large part of the production equipment and tools ourselves or optimize them as required.

In cases where automation of production cannot be the means of choice, we can also manufacture components manually at high quality and speed.

At B&S, we have a wide range of assembly options and can offer both manual and automated production processes depending on the requirements of our customers.

We provide our customers with comprehensive advice and find the right solution for every project.

From prototype to production, we at Bernhardt & Schulte are the sole contact for your serial production using plastic injection molding. Our in-house mold construction enables us to intervene in production processes as quickly as possible.

Individual switching systems in line with customer requirements provide us with the opportunity to prove our capabilities in the electrical and electronics industry.

For required complex functions, B&S produces technical plastic molded parts using the injection molding process for every industrial sector.

With B&S injection molding technology, inserts can be reliably overmolded around complex components with thermoset or thermoplastic.

We manufacture high-quality and custom molds for your field of application. You will benefit from B&S many years of expertise.

Bernhardt & Schulte GmbH & Co. KG

Oststraße 20

58540 Meinerzhagen | Deutschland

Telefon +49 (0) 2354 926 5

Fax +49 (0) 2354 926 340

Bernhardt & Schulte GmbH & Co. KG

Lagerhausstraße 12

96349 Steinwiesen/Ofr. | Deutschland

Telefon +49 (0) 9262 99 30 0

Fax +49 (0) 9262 99 30 20